The Behind Story and Making of Premium Flagship OPPO Find X5 Pro

Flagship phones create a dedicated space for premium features and excellent specs included in them. A vast variety of smartphones in the tech industry revolve around plenty of innovations. So, it is always hard to choose the finest from the best.

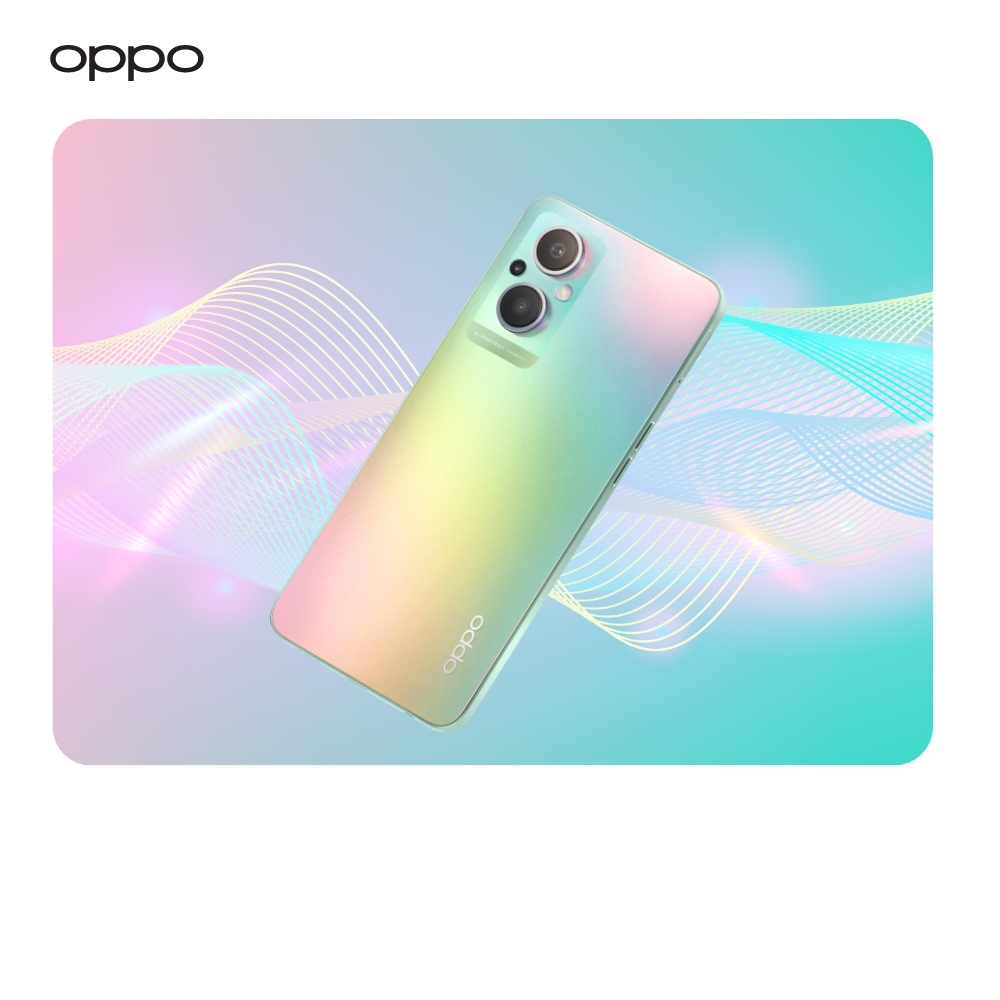

The OPPO Find X5 Pro is created with innovative engineering techniques that have never been seen before. This flagship handset utilizes ceramic material to craft a curved glass surface. The rear camera houses a volcano-like design that wraps around it to make the phone seem more elegant.

What makes the OPPO Find X series stand out from the crowd is its jaw-dropping design layout from every angle. The rival smartphones which feature similar rear cameras flaunt unnatural bumpy designs. However, with the OPPO Find X series, the volcano design forms naturally with a smooth surfacing. You can smoothen your finger-touch with caressing through the rear camera design.

Conquering Ceramic

Based on all the previous experiences, OPPO has built this Find X series mobile with the finest curvature. The ceramic rear has been used for the first time ever in Find X5 Pro. It also supports the properties of glass to the best for showcasing the stunning visual appearance. The ceramic is created with microcrystalline material. This material is reduced to 1000-degree Celsius temperature for the smoothest texture. This means the OPPO Find X5 Pro’s surface will have minimum trouble with any fingerprints. In addition, this material is also double times more solid than glass.

The back curved design of the Find X5 Pro is unique owing to the ceramic used in the phone. This material is superior to glass in more than one way. It is also highly resistant to any bumps, scratches and drops. With ceramic, one thing you can be sure of is a high-quality premium material with minimal downsides.

A Perfect Solution

OPPO Find X5 Pro’s build was initially being manufactured with similar existing methods. However, when OPPO realised that there will be a larger cap between the camera structure and the rear side, this problem was solved. This was done by arranging two blades at a 90-degree angle for a precise machining technique. Engineers used the blades to enhance the accuracy of the final product. Amidst that, a new problem occurred in the form of a cutting line with a straight edge, due to which the sides of the ceramic cover were surrounded. This happened because of the machine blade lines that also caused prominent cutting marks. While this issue is often neglected in other smartphone brands, OPPO did not choose to compromise here.

An entirely new lift-edge polishing procedure was created as a solution. Through this method, the machine edges were refined, improvised, and made smoother. In the mission of removing manufacturing marks, it was realised that most of the ceramic material was taken away in this process. As a result, the rear side design also became smaller to fit perfectly into the headset. So, to overcome this issue, engineers used polishing methods in multiple stages.

The four-axis polishing machine that has never been used before is used to accurately polish the edges of the ceramic. This machine particularly uses micron-level diamond powder to polish the edges totally. In addition, it is also regularly checked whether the polishing stages are completed, and adjustments are needed. To find a perfect end result of premium ceramic rear cover, there are precise adjustments made, down to 0.005 mm. In total, a total of five days is taken to produce polished, premium, and accurate quality design.

Brilliant Precision

The rear camera housing of the OPPO Find X5 Pro is brilliantly executed with a smooth volcano design. The foremost issue in most smartphones’ camera housing is the unexciting bump. But just as we mentioned earlier, OPPO has solved this problem with a perfect blend of its rear camera and entire mobile design.

Another problem that OPPO had to face while creating Find X5 Pro, was in fact, the blending of housing with cameras. For this, the camera ring needed to be removed carefully without being positioned too low or too high. If the lens could have been settled higher, the probability of damage will be greater. Similarly, in the case of lower adjustment of lens, the premium feel could have been lost. As a result, it is also difficult for the camera lenses to feel a dip in the surface. To avoid this, OPPO took a perfect placement of its lenses. The lenses were placed just below the ceramic housing with just 0.10 mm thickness.

The ceramic battery covers were separated into three groups based on their thickness. Similarly, the camera lenses were divided into three categories according to their thickness. For achieving precise and accurate depth into the housing, each of these lenses was matched with their adjoining ceramic cover.

The primary three lenses of OPPO make 27 combinations in total if we multiply 3x3. This makes manual grouping and measuring hard. As a result, the automated machinery by OPPO has been developed for grouping the lenses and rear covers automatically.

Bottom Line: The Ultimate Engineered OPPO Find X5 Pro

OPPO successfully fulfilled its commitment to engineering Find X5 Pro into a precision master. The amount of hard work, compassion and accuracy put into this smartphone makes it stand out with perfection. The OPPO Find X5 Series has also been awarded with the iF Design Awards 2022, which is another achievement unlocked.